Current Position:Home > PRODUCTS

Product Details

AutomationReplace manual laborEfficient

Automation equipment removes the risk of human error or injury from many of the manual, repetitive steps in the metal forming process. Automation also speeds up the metal stamping process for more efficient production cycles.Progardonx transfer equipment can revolutionize your metal forming processes. When your company’s metal forming operations require multiple stamping dies and/or processes to cre

PROGARDONX AUTOMATION EQUIPMENT

Automation equipment removes the risk of human error or injury from many of the manual, repetitive steps in the metal forming process. Automation also speeds up the metal stamping process for more efficient production cycles. Progardonx automation equipment includes:

SpeedFeeders. SpeedFeeders deliver the sheet metal material to the presses. They can push loads of up to 529 lbs (240 kg) through the metal forming process, and may be mounted on the floor or the press depending on the application.

Transfer systems. Many metal formed parts need to go through multiple processes. Transfer systems move partially completed parts from unit to unit so the whole process is automated.

Robots. Robotic components perform ancillary operations throughout the metal forming process. They handle the movement-based steps that connect different parts of the total operation.

Blank de-stackers. De-stackers prepare metal sheets for metal forming. They ensure the separation of stacked sheet metal to reduce errors. They also lubricate and precisely position the sheets so the presses can perform their function without any need for manual adjustment.

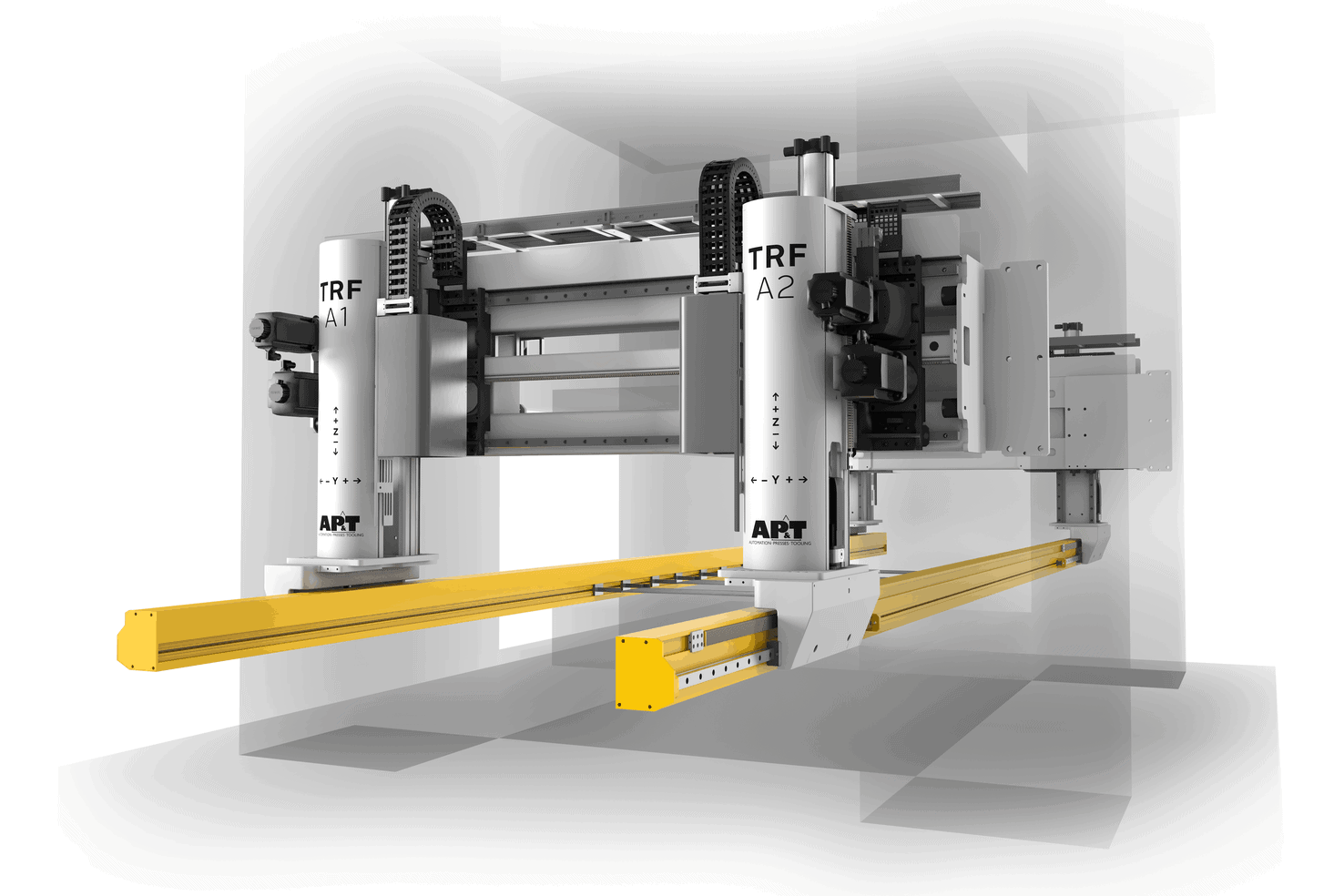

PROGARDONX TRANSFER

Progardonx transfer equipment can revolutionize your metal forming processes. When your company’s metal forming operations require multiple stamping dies and/or processes to create the finished product, transfer units speed up the operation.

Transfer feeders reduce material consumption and labor costs. High acceleration rates increase your output and the ability to automate transfer rail exchange reduces setup time.

Progardonx equipment uses modular designs with multiple standard weight capacities. This allows for customized application of standard product, rapid installation, and ease of expansion while maintaining an efficient price structure because they’re not recreating the wheel each time.

Standardized designs and components are used so you get proven designs, resulting in ease of maintenance.

Options to suit your application include:

Extra transfer rails

Electronic synchronization features

Flipping stations

Active grippers